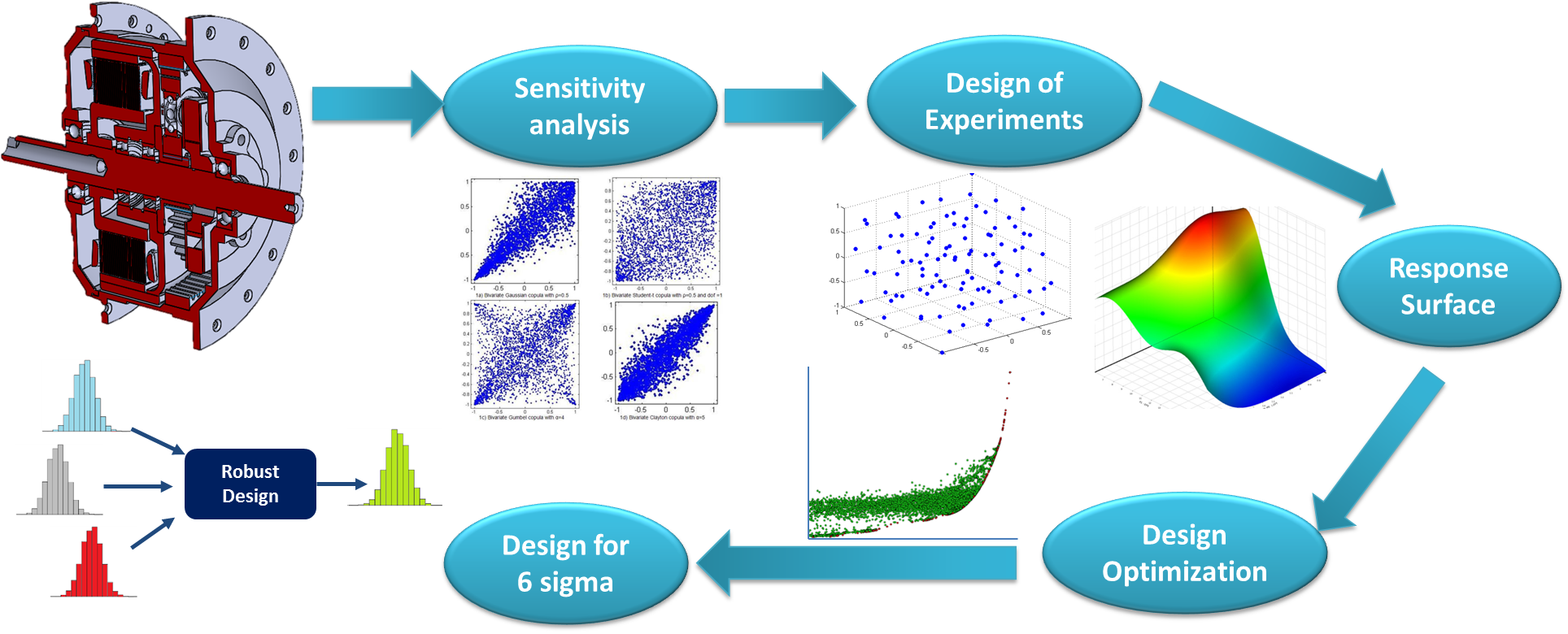

Evaluation & Optimization

Performance evaluation and robust design is essential in today’s competitive market. We have the know-how and tools to evaluate quality of current design subject to variations in material, manufacturing process, environment and effects of aging. We can then optimize the design for improved performance and make it robust to above variations.

We have the capability of evaluating and optimization large systems based on lumped parameter models. We use ANSYS Design Explorer and Matlab/Simulink optimization toolbox.

We can also perform evaluation and optimization study based on experimental data.

Evaluation Criteria

Identify key performance criteria and cost model with client in order to establish quality goals.

Parametric model

Identify all potential design parameters and sources of quality variation with client. We then create an integrated parametric CAD & FE model and cost model in Excel.

Sensitivity study

Conduct parameter sensitivity study and identify key parameters related to performance and cost.

Design of Experiments

We create design of experiments and run automated simulations to generate response surface (or Meta model).

Design Optimization

Single and Multi-objective optimization based on meta model based on gradient as well as global optimization algorithms. Validate optimized design