Engineering Design

Idea Generation

Engineering design starts with the generation of multiple ideas (or ideation) to solve a physical problem. This process is based on fundamental physical principles and first-order engineering calculations, often done by hand. The process of ideation is generally a team effort and often leads to multiple solutions to a given problem. In fact, the success of the idea generation phase in terms of novel solutions depends upon having lots of ideas from diverse backgrounds including end-users of the product or service. Our approach is to develop concepts independently and then carry out effective brainstorming with our clients to crossbreed ideas and generate more concepts and combine good ideas to come up with a better overall solution to address a given problem. We leave no stone unturned to solve the problem. Several ideas are down-selected and then evaluated based on logistics, costs, simplicity, ability to manufacture, etc. All intellectual property developed during the course of this process is transferred to the client.

Conceptual Design

In this phase, the down-selected ideas undergo a conceptual design phase. In this phase, it is often necessary to carry out simple physical experiments or even simple engineering simulations to quickly validate concepts. At the end of this exercise, a single concept is down selected for detailed engineering analysis. During the conceptual design phase, initial material selection, size, and performance estimation is carried out.

In this phase, we focus on key functional & regulatory requirements and risk mitigation. This lean approach is beneficial in evaluating concepts quickly & cheaply.

- Virtual prototyping using CAD models and motion analysis or low fidelity FEA (finite element analysis) to evaluate functionality.

- Topology optimization for generating structural concepts.

- Develop simple physical prototypes using rapid prototyping tools.

- Evaluate & down-select concept based on key functional, regulatory & manufacturing requirements.

Detailed Design

The detailed design process initiates once we have settled on a single conceptual design. This process goes through multiple interdependent phases:

Material Selection

We identify material, manufacturer & manufacturing process early in order to save time and money in later phases. Material Selection is an important part of the design as it relates to form, function, and manufacturing process. We use state of the art method of material selection consistent with functional requirements.

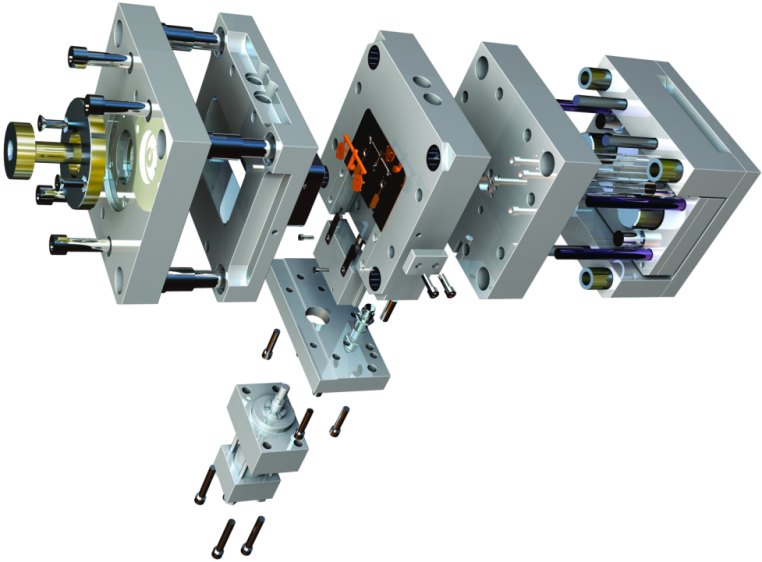

Design for Manufacturing & Assembly (DFMA)

Design for manufacturing & assembly starts with DFA (Design for Assembly ) to reduce part count and then to DFM (design for manufacture). The key benefits of DFMA is lower assembly time and related costs such as rework, inventory, and cost of fasteners. From a functional point of view, this means reduced risk of connection failures due to bolt holes, welded and bonded joints.

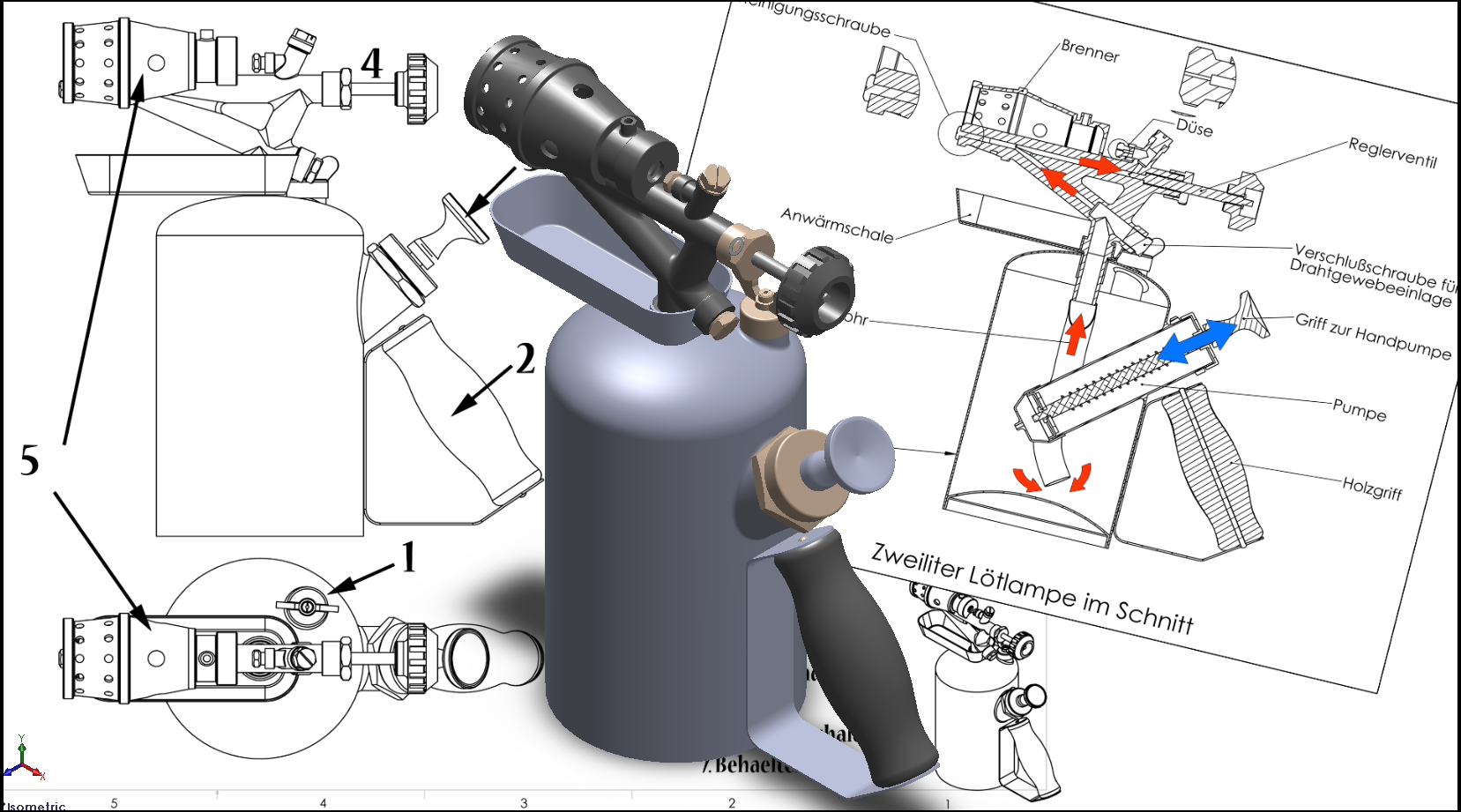

Computer-Aided Form Generation

We use experience coupled with CAD or computer-aided design to generate component shapes and assembly configuration. The form is generated to meet aesthetics, functionality, assembly, manufacturing and regulatory requirements.

Design Evaluation or Analysis

In this phase of detailed design, a computer model of the design is simulated by means of state of the art finite element analysis (FEA) or computational fluid dynamics (CFD) simulations. Please see our advanced simulation services for more details.

Detailed CAD (Computer-Aided Design/Drafting)

After the design passes rigorous analysis and evaluation, the last phase is detailed CAD for the development of the prototype.

- Computer-aided design for all components, sub-assemblies, and main assembly.

- BOM (bill of material)

- Generation of Detailed drawings

Prototype Testing

The last phase of the design is testing the prototype under realistic operating conditions. In some cases, test rigs are developed to carry out testing in a controlled environment. We have complete expertise in developing test rigs. We can also carry out tests for our clients including post-processing of test data. Please see our test rigs and testing services for more detail.